Turbidity Barriers

VOLUME PRICING AVAILABLE:

1-4 rolls, 5-10 rolls, 11-20 rolls, 21+ rolls

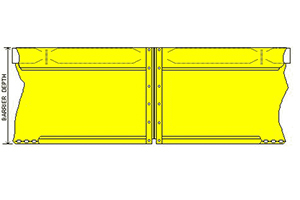

Floating Turbidity Barriers or Floating Turbidity Silt Curtains

These consist of a top flotation boom, an impervious fabric curtain extending downward under water, and a heavy galvanized steel chain sealed into a hem along the entire bottom of the curtain to provide ballast to keep the curtain vertical in the water. End hems are sealed around a rope and grommeted to allow attachment to each other with rope or bolt/nuts/washers.

The most frequently specified barrier in the TOUGH GUY® line. It is recommended for construction sites located in protected areas that are exposed only to light winds and to current velocities of less than one foot per second. This type of site may include ponds, shallow lakes, small streams and marshes.

Anchorage consisting of stakes or concrete blocks may be required to maintain the barrier in its required position. Barrier sections are connected by rope lacing or nylon ties which must be furnished by others.

The work horse of the TOUGH GUY® line. It has a top load cable and special stress plates for reinforcing the corners and is designed to handle more severe conditions. It is recommended for lakes, streams, intercoastal and tidal areas where current velocities up to five feet per second are expected.

The anchorage and installation must be designed to meet the site conditions. Contact a qualified engineer for assistance when extraordinary site conditions are encountered. Barrier sections are connected by rope lacing or nylon ties which must be furnished by others.

Type 3

This is a special adaption of the Type 3 barrier. Approximately 20 % of the area of the barrier skirt fabric is replaced with a polypropylene filter fabric conforming to some State DOT specifications. The filter fabric is inserted to reduce the pressure on the curtain while retaining silt. In actual practice, a filter fabric which is woven tightly enough to retain silt will not significantly reduce pressure on the curtain. Conversely, if the filter fabric is woven loose enough to reduce the pressure on the curtain, it will not be able to retain most silt and sediment particles. In addition, the filter fabric cannot be heatsealed, and must be sewn into the curtain, resulting in a reduction in curtain strength and longevity.

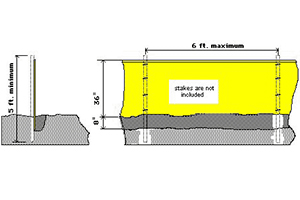

Staked Barriers

These are continuous panels of impervious vinyl-polyester fabric that, installed correctly, can contain stormwater runoff or re-direct it to proper channels or retention areas. On-land installation is similar to that of silt fence, with 8 inches below grade and 36 inches above grade attached to stakes. Staked Barriers can also be installed in up to 18 inches of water.

The fabric curtain has a heat-sealed hem along the top edge and is approximately 44 inches wide. A narrow trench 8 inches deep is dug along the perimeter line and stakes are driven every 6 feet along the downslope side of the trench. The upper portion of the barrier is attached to the stakes with staples, wires, or nylon ties, keeping the top of the barrier 36 inches above grade. The lower edge of the curtain is placed in the trench which is then backfilled. This system works best in porous soils on moderately sloped sites. The stakes may be wood or metal. Stakes are not included and must be purchased separately. Ask your sales representative for more details.

- Type 1 DOT Floating: 5′ x 50′

- Type 2 DOT Floating: 5′ x 50′

- Type 3 DOT Floating: 5′ x 50′

- Staked Turbidity Barrier: 44.5′ x 100′