The cold weather and shorter periods of daylight make for higher risks and opportunities for accidents. The true danger of winter weather is not what you can see, but what you cannot. From black ice blending in with asphalt, to fluffy white layers of powder concealing ditches, unseen threats can cause damage to equipment and injury to workers.

To minimize risk and prevent your machines from becoming another unseen hazard, here are tips to keep your operations running smoothly this winter:

Review Winter Driving & Cold Weather Safety Procedures

Prevent losses and maintain productivity this season by training all equipment operators on winter driving techniques. According to OSHA, employers should train all vehicle and equipment operators for winter driving safety as well as ensure all operators are properly licensed for the vehicles they operate. OSHA also suggests finding open spaces like empty parking lots to practice navigating icy surfaces for new drivers and those who are unexperienced operating heavy vehicles in winter weather. Teach drivers how to safely approach slippery roads and surfaces, windy conditions, damaged power lines and equipment, and anywhere else they are likely to skid, or lose control of their vehicle.

- Prevent downtime due to neglected machine maintenance. The undercarriage of a machine is responsible for 40-60% of its maintenance cost over the machine’s service life, depending on the type of machine. Maximize the efficiency of your machines in the winter by having equipment operators conduct daily inspections to ensure the undercarriage is clear and clean of any snow, mud, and debris that could increase the operation costs of your equipment. Investing a little time before conducting work each day can save thousands of dollars in repairs in the long term.

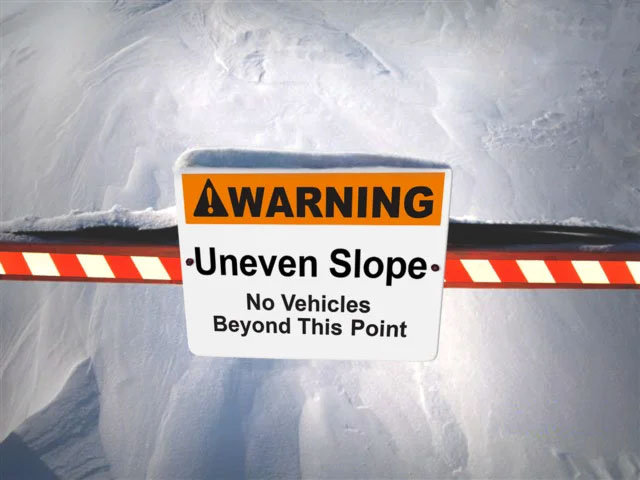

- Install effective traffic control devices. Making stop signs, barricades, and other traffic control devices more visible helps everyone navigate safer and reduces risks to man and machine. Implement reflective and high visibility signs to clearly identify active work zones and quickly communicate safety instructions. Apply additional lighting, barrels, cones, and barriers to mark and outline work zones and hidden lane markings. Prevent the chances of workers being struck by vehicles or mobile equipment and ensure all workers wear high-visibility vests or other devices so they are visible to drivers.

- Train workers how to recognize cold-related illnesses. The National Institute for Occupational Safety and Health (NIOSH) says contractors who are exposed to extreme weather conditions, such as freezing temps, may be at risk of cold stress. Most commonly, this is due to working in cold conditions for long periods, leading to high risks of hypothermia, frostbite, and trench foot. Ensure you and your workers understand the danger signs including “uncontrolled shivering, slurred speech, clumsy movements, fatigue and confused behavior” (OSHA).

Implement Modifications to the Jobsite

Modifications to procedures and additional safety precautions may be necessary due to winter weather conditions. You can determine this by conducting a Job Hazard Analysis (JHA) of work areas. Develop a winter worksite checklist and conduct a walk-through to identify areas where winter weather could introduce new hazards such as falling ice, slick or frozen surfaces, electrical hazards, and more.

Workers are more likely to be killed by construction vehicles that are operating on the worksite during highway construction operations. Also, 75% of motor vehicle accidents occur during daylight hours on highways; which does not take into account poor visibility that winter introduces. Poor visibility plays one of the most dangerous roles during winter and can be fatal if workers are unprepared. Keep them safe by implementing the following safety controls on the jobsite:

- Inspect working surfaces that may not be as accustomed to cold weather. Ensure you understand the materials you are working with and the proper methods to use to get the best results in the winter months

- Ensure routes are clear. Ice and compact snow often hide edges, ditches, and uneven surfaces that may not be able to hold a heavy vehicles weight

- Ward off unsafe areas with visible barricades and visuals

- Ensure workers know where snow plow areas are by clearly marking roads and sections of the jobsite that need to be plowed

- Provide more light if operators cannot see what’s in front or above them

Enhance Visibility from All Angles

Reaction times are drastically reduced in winter due to slippery and icy road conditions. In the event of a sliding vehicle, effectively draw attention to moving vehicles, workers, equipment, and surrounding hazards using highly reflective and high-visibility material:

- Apply high intensity reflective tape for increased daytime and nighttime visibility for long distance viewing. It’s ideal for traffic signs and personal protective equipment (PPE) like hard hats and safety vests.

- Apply reflective stick-on shapes to add reflection wherever needed like snow plows and vehicle fenders, other equipment and machinery, PPE, and smaller items like tools and emergency equipment that may be difficult to find or see in low-light situations.

- Warn other vehicles to keep a safe distance from plows and other road maintenance and construction machinery with bold signs that are easy to read.

- Avoid operating machinery in poor light conditions. Vehicle headlights alone may not be enough to effectively display ground conditions or overhead hazards on construction or industrial sites. Provide temporary signs or labels that indicate hazardous areas if operations are possible.

Regardless of your location and work environment, ensure your workers are physically taking care of themselves and are trained on all changes and modifications to their normal working procedures in the winter season. With reflective tape and custom, highly visible signs and labels, you can ensure safer winter operations.